Trends of the Pharmaceutical Industry is changing with huge pace and there is strong need of creating the Quality Assurance who has acquired skills in all dimensions so as to combat and sustain in this highly volatile environment with high level of competition. In this article we will ten discuss such skills which are the need of time.

There are various calculation and formulas required for the Calculation of MACO (Maximum allowable Carry Over), PDE (Permitted Daily Exposure) and NOEL (No Observed Effect Level) in Cleaning Validation. All these formulas are helpful in implementing the correct cleaning validation matrix and plan at facility. Herewith are detailed full proof […]

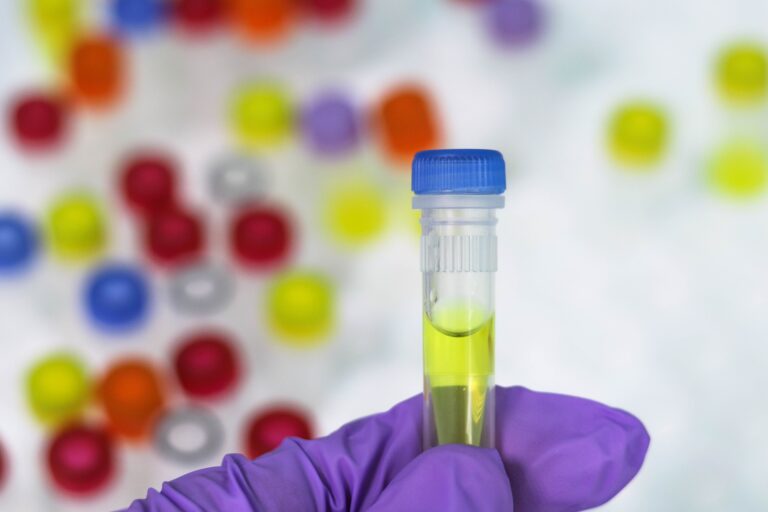

USP chapter 〈1790〉 titled ‘Visual Inspection of Injections’, is the most efficient document that describes every single aspects which should be taken care while performing the validation of visual inspection process for the sterile injectables.

Pharmaceuticals Sterile Injectable Manufacturing and Filling Line produces a variety of products including liquid and lyophilized types, therefore a risk based rationale should be adopted with permutations and combination of Batch size, fill volume, filling speed, filling duration, container closure type, process or steam sterilization, product form (liquid or lyophilized), mode of product sterilization (filtration, terminal sterilization, aseptic process etc.), Inert gassing after filling of containers, equipment trail etc.

USFDA release the guidance documents on Process Validation titled “Process Validation: General Principles and Practices” in January 2011. However the approach laid down in this document is still being not adopted completely by the industries till date. The concept laid down was to transfer the complete process optimization activities to R & D from manufacturing instead of struggling during the Production phase. This would lead to cost saving and reduces the chances of failure of the product when it has been transferred to the manufacturing phase.

Fate of your decision lies in data accuracy. When you take a decision, it may be a good decision or a bad one. However the same is completely dependent on the accuracy of the data being evaluated by you, same applies to the Management Information System also.

The decision of the management may go wrong in case there is inaccurate data and inadequate Management Information System.

These are the two sides of the same coin, however, they are taught to us in different way.

Air Flow Pattern or Smoke studies have been one of the interesting areas for the Inspectorates, nowadays. There is very low amount of attentions being paid by the organization when we are designing the smoke pattern protocols and reviewing the videotapes. Sometime situations are there companies do not understand how to review the Air Flow Pattern or Smoke study recordings. This article shall explain everything on the topic and bring the clarity on each segment of Air Flow Pattern. It will make Smoke Study so simple.

Pharmaceutical and Biopharmaceutical industries must develop the strategies to eliminate the Data Integrity from their Organizations. However, the biggest problem is that the Organization are bounded with multiple myths which stops them to come out of the issues pertaining to data Integrity. Five biggest myths which are hindering in the […]

Performance & Productivity are the two common parameters that are frequently measured within the organization. However, it is important to understand that both the parameters are highly influenced by the engagement of the employee (in terms of their feelings & emotions) with the organization. Research proves that engaged employees are better performers as compared to the disengaged employees. Below mentioned 7 strategies will give you insight how the employee engagement of the organization can be enhanced.

Success Principles by Raman Mehta describes the 8 Principles of Guaranteed Success!